Dieser Internetauftritt erhebt persönliche Daten. Informationen dazu finden Sie beim Impressum. Verlassen Sie die Seite, wenn Sie damit nicht einverstanden sind. Mit der weiteren Nutzung der Seite stimmen Sie der Datenerhebung zu.

Online measurement device for thermal power plant and water filtration

We offer products and support

for:

- Power plants (thermal as: CCGT, coal, nuclear, RDF)

- Water treatment (tap water, process water, circulating water

in industy, pool,

and power plant)

- District heating grid.

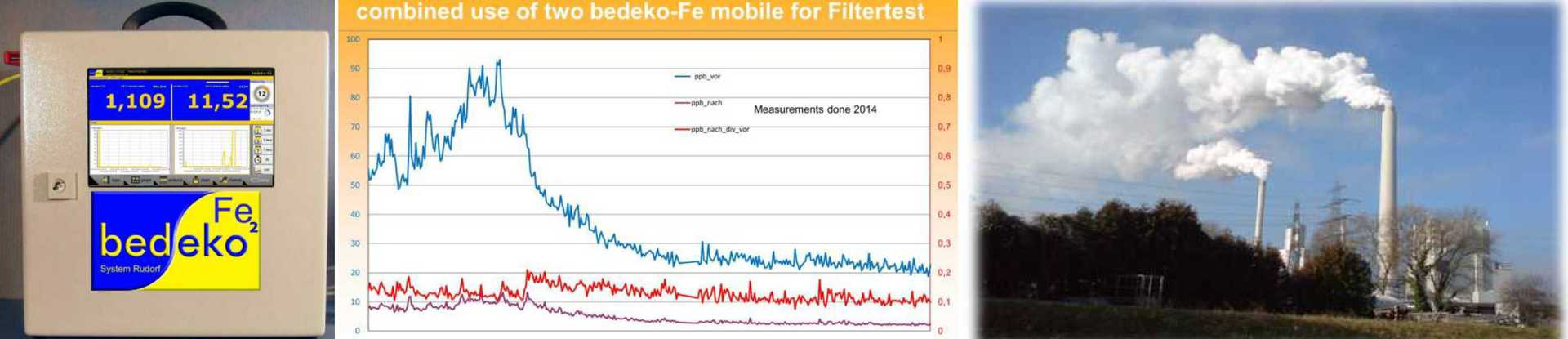

Since 2013 the re-engineered bedeko Fe is available again as unparalleled monitoring device for iron concentration, capable to monitor online continuously that corrosion product in water-steam-cycle of power plant units. Time resolution is 1 minute at a reaction time depending mostly on tube length.

Concentration range: 0.1 to 10,000 µg/L Fe

Compact – sturdy – quick – low detection limit. Affordable.

More information is available from

About us

Our main product is designed for online-monitoring of iron concentration in water-steam-cycle of thermal power plant units. This is especially useful to check function and efficiency of filter systems or monitoring of corrosion process effects suspected to be threatening turbine or boiler. Due to low maintenance needs and low cost for operation permanent monitoring is cheap. This helps to detect even little changes by easy comparison of each moment to any previously detected and recorded situation. And it will alarm specialists to take over deeper investigation if needed.

We give support to owners or

operators of such monitoring systems to select appropriate products or methods to run their power plant units at low wear. We offer support on analysis and interpretation of measurement data as

collected during normal operation or commissioning as well as for fault detection.

We do not only sell but also rent bedeko products, if needed the man power to install and supervise those measurement devices can be provided. This can be ordered when problems need to be solved quick and at high efficiency. Such situations may be found during commissioning of newly built units as well as when strange findings are made during daily operation.

Verification of guaranteed values during commissioning of newly built installations more and more is needed. This is true for condensate polishing or filtration, as well as for steam quality during start-up or runs under typical conditions. bedeko Fe does support such checks and it is piece of cake due to simple and quick installation and ease of use.

This helps to identify in situ any discrepancy between plannings and real situation. Therefore repair or adjustment can start early which helps to do delivery without violation of limit.

Additionally this supports

operators to prevent from contamination of components that later are hardly to be cleaned and therefore are suspect of threatening operation of the turbine,

e.g..

We are ready to support you to win the future.

Solving problems – not just adding another one.